-

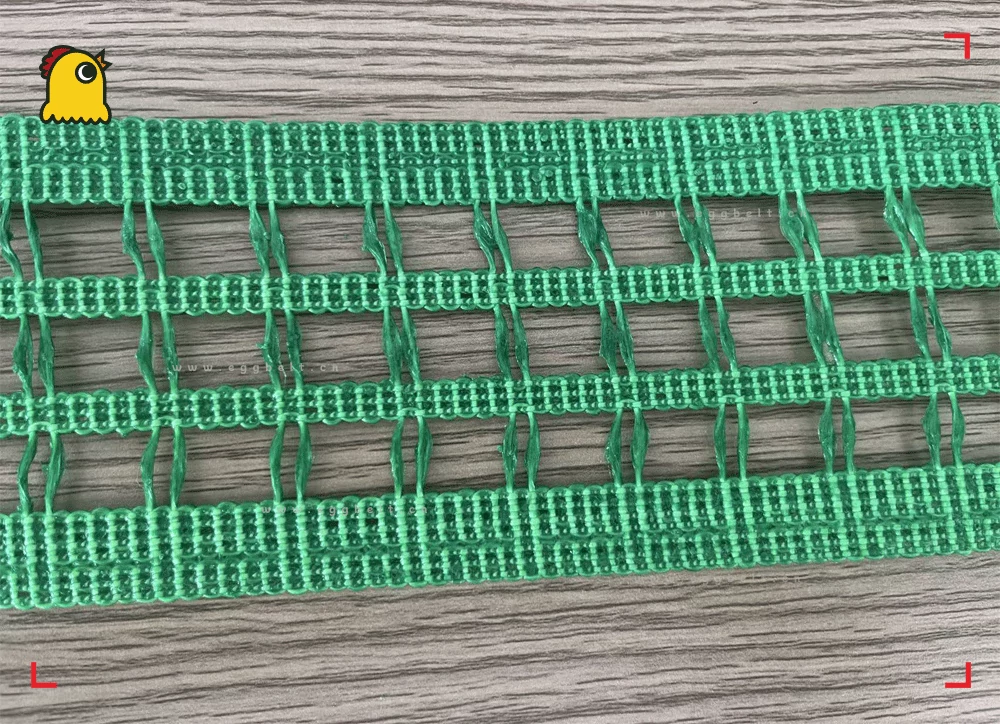

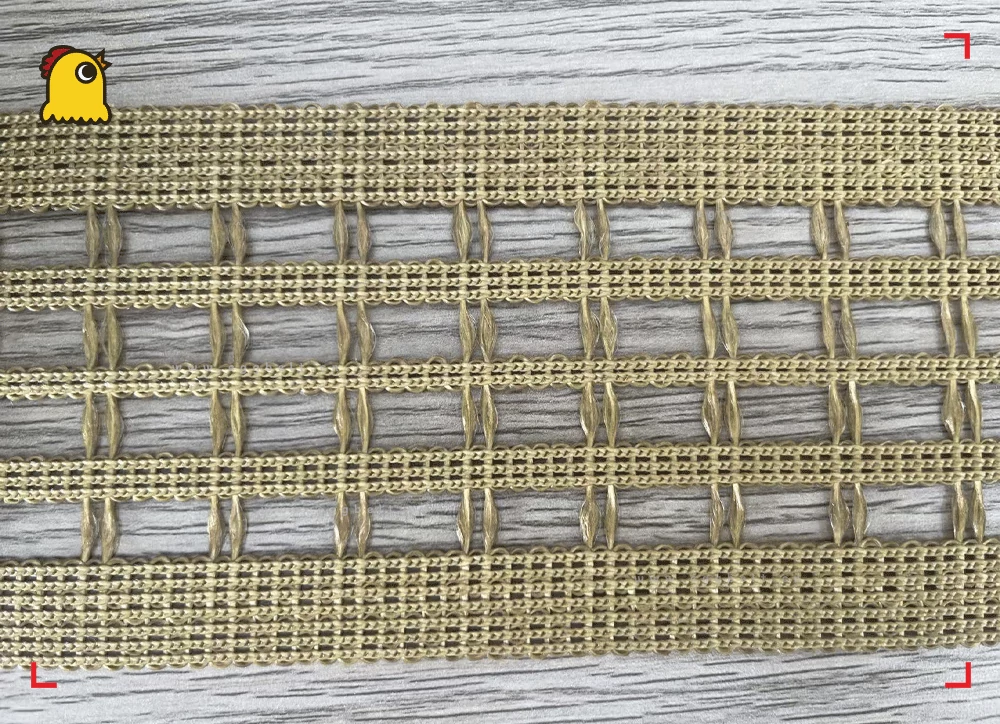

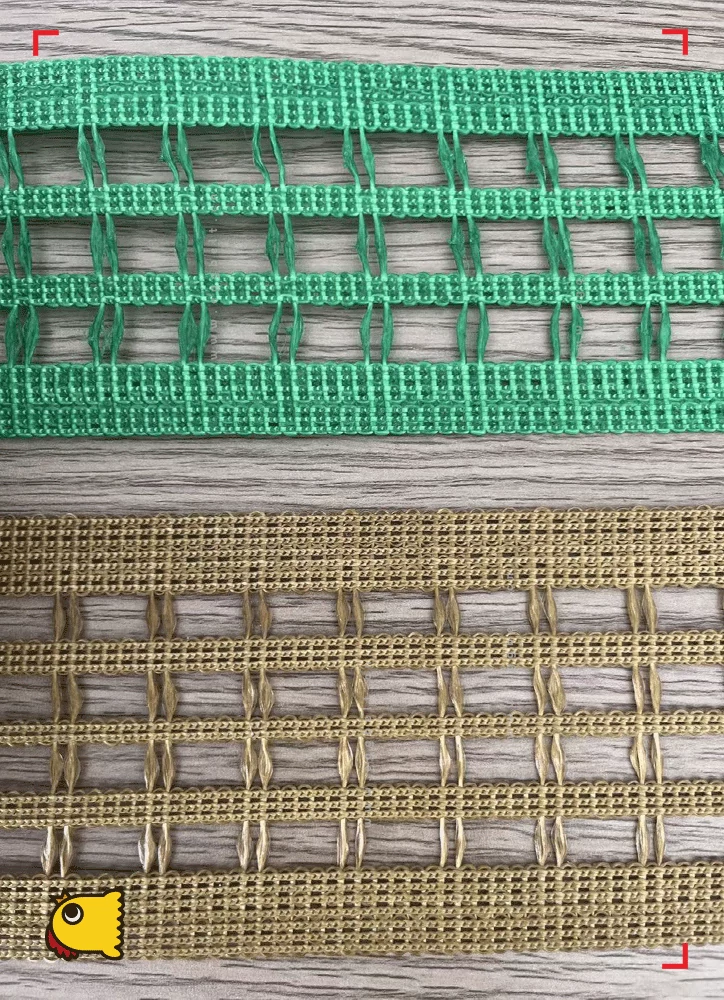

Eco-Friendly Composite Construction

• Made from a synergistic blend of high-density polyester fabric and food-grade PVC, using only virgin, eco-friendly raw materials—free from recycled fillers or harmful plasticizers.

• Meets international standards for poultry equipment safety and sustainability, ensuring zero chemical leaching onto eggs or into the farm environment.

-

Extreme Wear Resistance

• Leverages PVC’s inherent abrasion resistance and UV-stabilized anti-aging formulation to withstand daily friction from eggs, cages, and cleaning systems.

• Field-tested in high-density layer houses for over 3 years with<5% surface degradation, significantly outperforming standard rubber or PE belts.

-

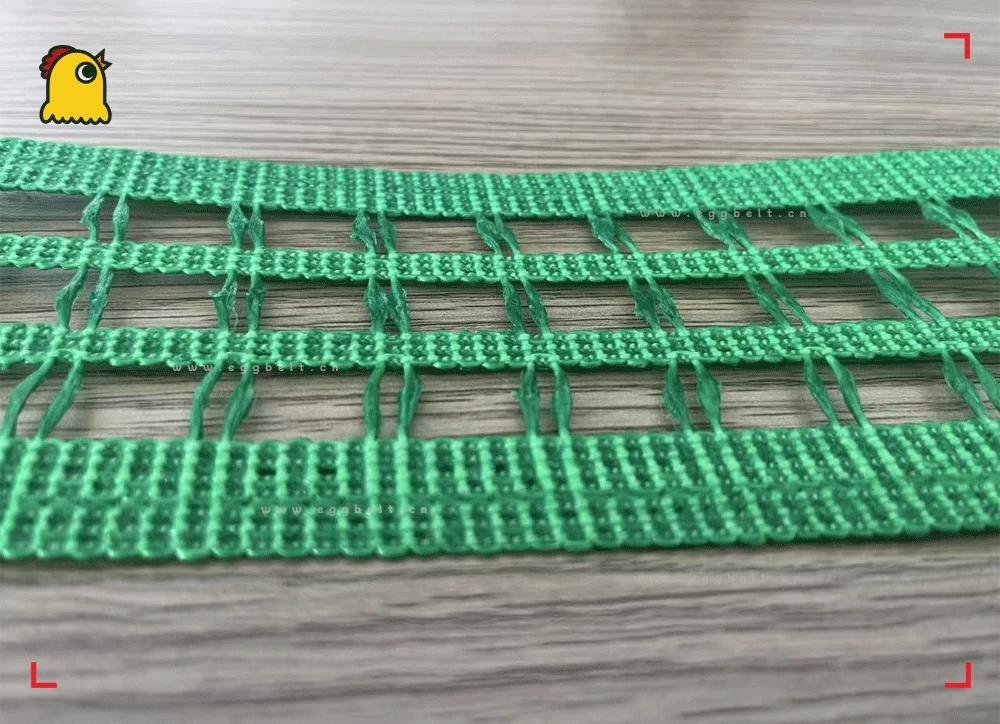

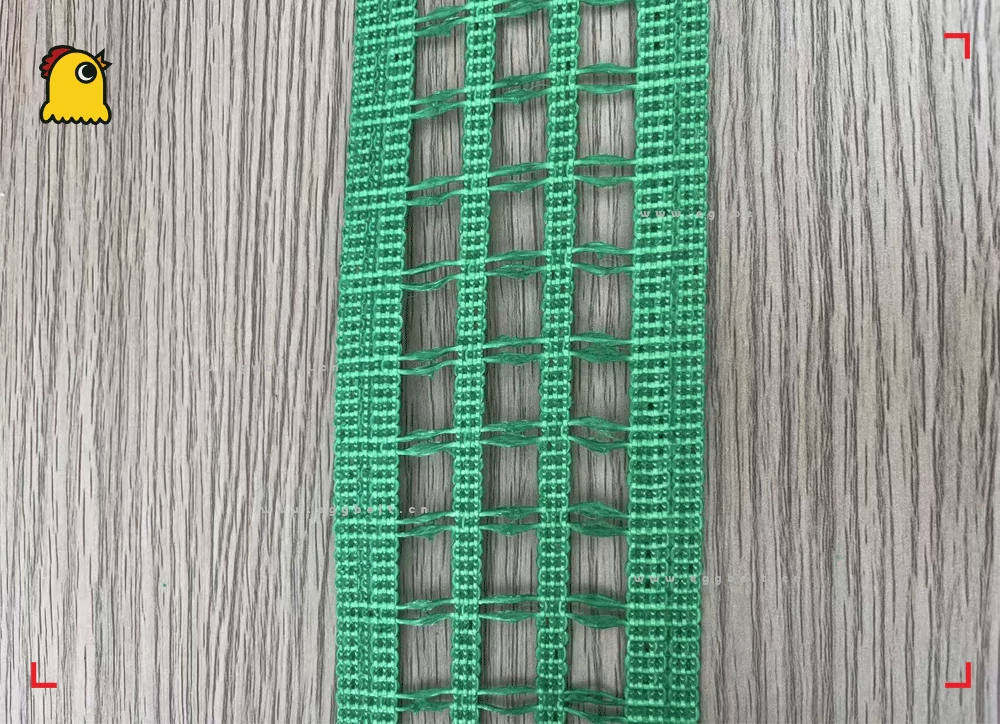

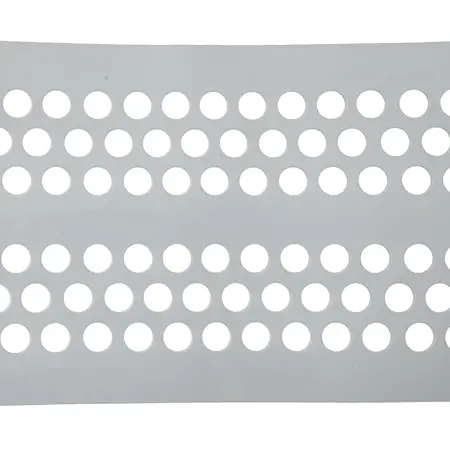

Breathable Perforated Design

• Precision-engineered micro-perforations allow rapid drainage of moisture, manure dust, and feed residue, keeping egg contact surfaces dry and clean.

• Optimized hole pattern prevents clogging while maintaining structural integrity—reducing manual cleaning frequency by up to 60%.

-

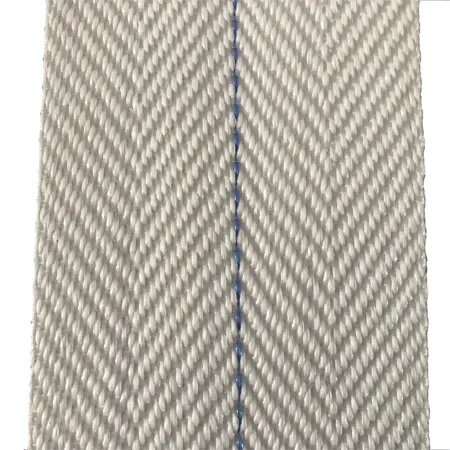

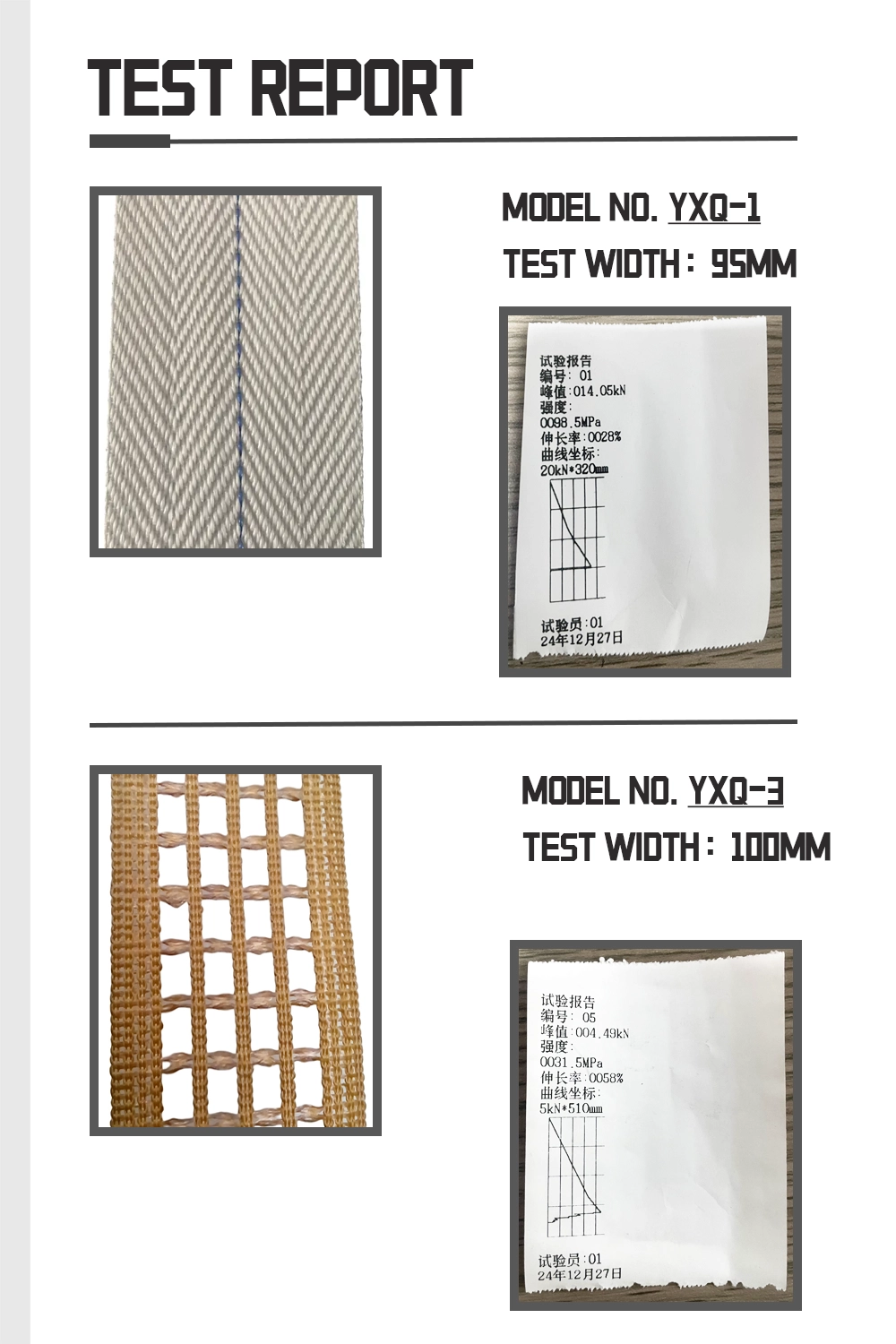

Enhanced Tensile Strength

• Reinforced composite core delivers tensile strength ≥ 280 N/cm with zero fraying, stretching, or edge deformation under continuous load.

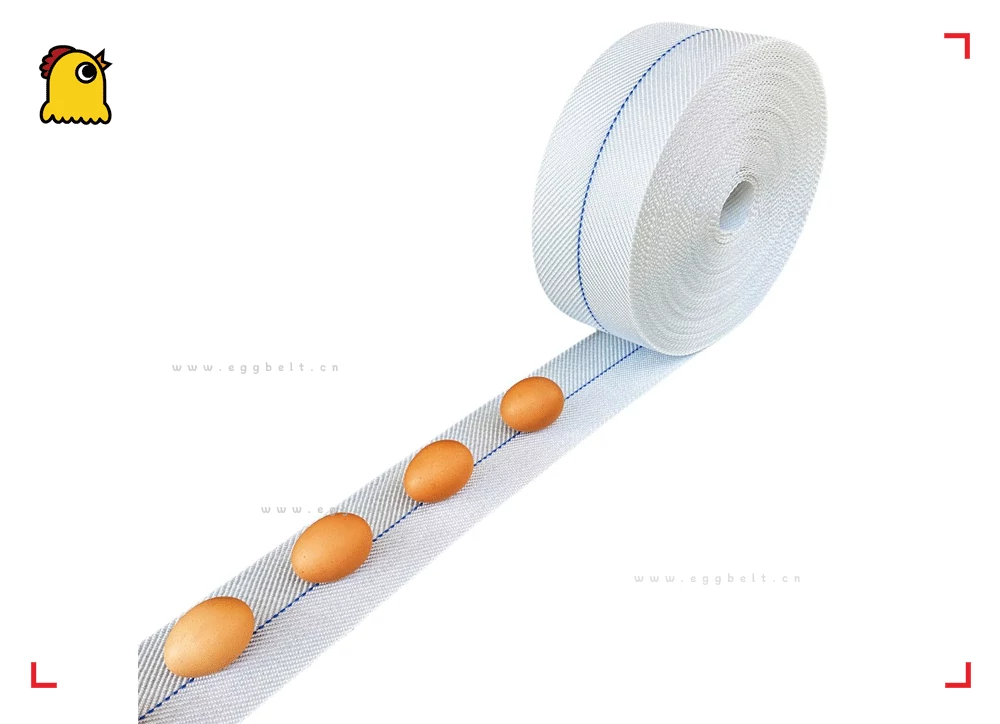

• Seamlessly integrates with automated collection systems, eliminating belt slippage or misalignment even during peak laying hours.

-

Long Service Life

• Designed for a minimum service life of 5 years under normal poultry farm conditions—cutting replacement costs and maintenance labor by half compared to 2nd-gen belts.

• Real-world data from 120+ farms shows >92% of belts remain fully operational beyond 60 months, offering the lowest total cost of ownership in the industry.

简体中文

简体中文